Shipping Items Safely: The Value of High-Quality Pallets

In the modern world of logistics and supply chain management, the significance of safe goods transportation is paramount. A key component of this process is utilizing high-quality pallets, that offer a solid and dependable base for transferring products from one location to another. Regardless of whether you are transporting fragile items nationwide or housing heavy equipment in a storage facility, pallets serve as a crucial element in ensuring that goods remain secure and intact throughout their journey.

Pallets act as a bridge between various stages of transportation and storage, allowing for streamlined handling while lowering the chance of injury. The design enables simple stacking and maneuverability, which makes them crucial in storage facilities and transport scenarios. As businesses increasingly demand efficiency and safety in their operations, the value of using high-quality pallets becomes ever more apparent. Not only does investing in sturdy, durable pallets secure products but also boosts total productivity and lowers costs related to damaged stock.

Types of Pallets

Pallets come in numerous types, designed to meet the unique needs of various industries and applications. The most frequent types are timber pallets, plastic pallets, and metal pallets. Wooden pallets are widely used due to their robustness, cost-effectiveness, and accessibility. They can bear considerable weight and are suitable for a wide range of goods. However, they may be sensitive to moisture and pests if not treated properly.

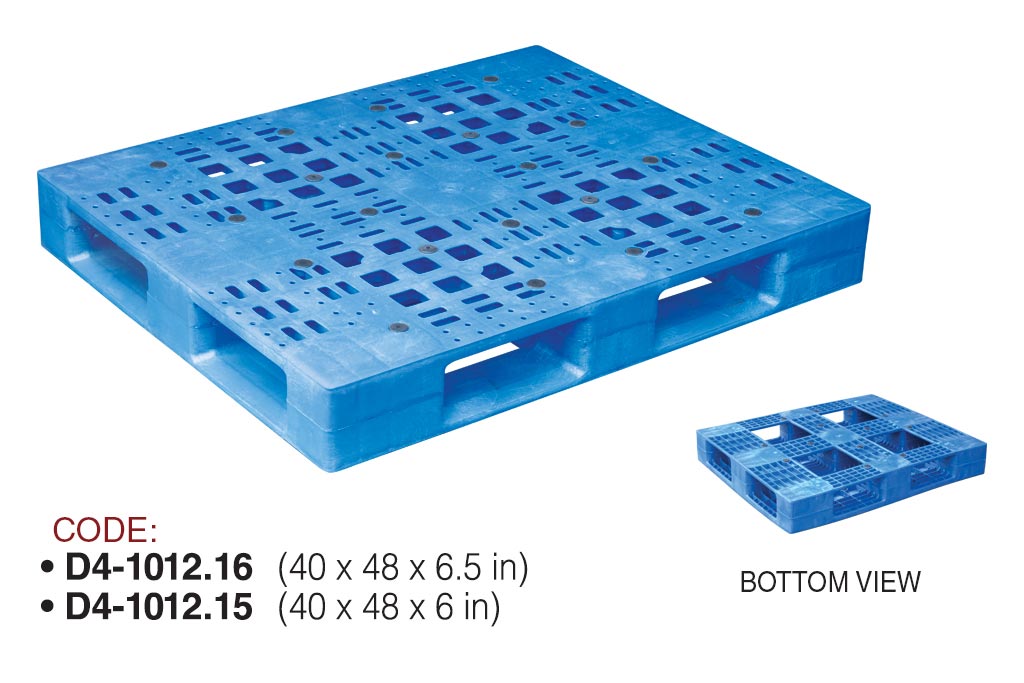

Synthetic pallets are growing in popularity because they are easy to handle, long-lasting, and impervious to moisture and chemicals. They can be readily sterilized, making them suitable for industries such as healthcare and food. Additionally, plastic pallets do not splinter, reducing the risk of injury during handling. While they may be more pricey initially, their durability can lead to savings in the long run.

Aluminum pallets, often made from aluminum, are designed for robust applications. They are exceptionally strong and can support significant weight, making them ideal for heavy settings. Metal pallets are also tolerant to environmental factors, including combustion and extreme temperatures. However, their cost and weight can be drawbacks, which limits their use in specific scenarios. Each type of pallet has its pros and cons, making it important to choose the best type based on distinct operational requirements.

Significance of Quality Materials

The choice of building materials used in pallets plays a key role in ensuring the safe shipment and storage of goods. High-quality materials boost the durability and load-bearing capacity of pallets, making them capable of withstanding the challenges of transport and handling. A well-built pallet made from sturdy wood, plastic, or metal can greatly reduce the risk of damage during shipment. This strength not only provides assurance for shippers but also makes certain that products arrive at their destination in perfect condition.

Additionally, superior materials contribute to the overall effectiveness of supply chain operations. Pallets that are made from trustworthy materials are less likely to snap or bend under stress, lessening the likelihood of workflow delays. In turn, this reduces the chances of monetary losses associated with damaged goods and unexpected downtime. Spending in durable pallets can enhance logistics processes, leading to smoother operations and greater customer satisfaction.

Additionally, using superior materials in pallet construction can enhance eco-friendliness efforts. Many manufacturers are now concentrated on environmentally friendly materials that not only fulfill performance standards but also reduce environmental impact. By selecting sustainable pallet options, businesses can enhance their overall environmental impact while still guaranteeing that their goods are shipped safely. This commitment with green goals can also resonate positively with consumers, further bolstering brand image.

Best Methods for Safe Transport

To guarantee the safe transport of goods, it is crucial to utilize high-quality pallets that can endure the rigors of handling and movement. Commence by selecting pallets that are suitable for the items being transported. Consider factors such as the weight capacity, material, and condition of the pallets. Wooden pallets, for example, are often rugged and able to hold up heavy loads, while plastic pallets may provide further resistance to moisture and chemicals. Frequently inspect pallets for any signs of wear or damage to prevent accidents during transit.

Accurate loading practices are vital for maintaining stability during transport. Ensure that pallets in tulsa is evenly distributed across the pallets, putting heavier items at the bottom and lighter items on top. Fasten loads with straps or shrink wrap to minimize movement, which helps prevent damage both to the goods and the pallets themselves. Additionally, refrain from overloading pallets, as this can lead to breakage or tipping, particularly during transit on various surfaces.

In conclusion, train all personnel involved in handling pallets on secure transport practices. Adopting standardized guidelines for loading, unloading, and stacking pallets can greatly reduce the risk of accidents. Foster a culture of safety where employees understand the significance of using quality pallets and adhere to guidelines diligently. Effective communication and ongoing training can lead to a more efficient and safer transportation process, eventually enhancing the integrity of the goods being transported.